Ion exchange processing purifies and recycles the rinse water following the MicroLok processing. The result is pure, de-ionized water fed back to the rinse tank for re-use.

One of the challenges facing manufacturers today is the question of how to carry out metal coating while conserving water.

The meteoric growth of the oil and gas industry requires down-hole drilling components with corrosion protected surfaces. Zinc phosphate coating is one method used to protect these components from corrosion while in storage, which then provides break-in lubricity when the components are put into service.

Traditional zinc phosphate tank lines can consume 100,000 gallons of fresh water a month operating an 800-gallon tank line for one eight-hour shift a day. That is a serious problem in areas where restrictions have been imposed due to water shortages, or where normal city water and sewer services are not easily accessed. Now there is a way to reduce the 100,000-gallon water consumption to 1,000 gallons a month, while also eliminating contaminated water discharge into the environment.

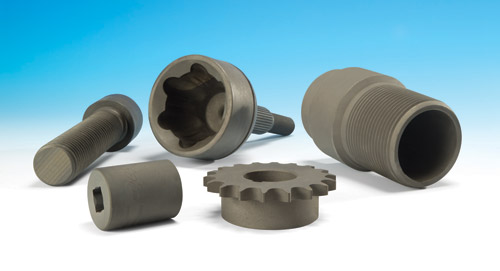

Zinc phosphate coating is widely specified as the coating of choice to form a friable, sacrificial surface treatment that improves break-in lubricity of mating/sliding surfaces, such as piston/cylinder assemblies, gears, bearings, etc. In addition, it is an effective treatment to eliminate galling of critical threaded parts, such as couplings, that must withstand repeated make-up/break-in cycles in order to function properly in the field.

Because the EPA regulates the zinc component in zinc phosphate, configuring the process line in a way that prevents the zinc from entering the drain is necessary. In most cases, an extensive zinc precipitation system is required to collect the zinc and precipitate it as sludge to be disposed of as hazardous solid waste. For large process lines, this system can work well, albeit with high capital costs.

Another option for treating the zinc is to utilize ion exchange technology to remove the zinc and purify the water so that it can be re-used. However, this treatment method works only on the rinse following the zinc phosphate tank. The other rinses in the process line usually go directly to the drain. However, when the objective is minimal fresh water usage, these secondary rinses can be treated with the Near-Zero Water Recycler system. The user achieves clean rinsing conditions while using minimal water when combining the ion exchange and Near-Zero processes.

Layout of the Near-Zero System Combined with an Ion Exchange System

When a large Oklahoma manufacturer of down-hole components for the oil and gas industry ran into water restrictions for its zinc phosphate process, the company installed a MicroLok MZN zinc phosphate process line. It solved the water restriction problem for its 840-gallon tank system that processes up to 10,000 lb of parts per shift. In a normal configuration, this process line would consume about 90,000 gallons of fresh water per month.

Because the plant is located in an area that has experienced severe drought conditions, the supply of fresh water is both limited and expensive. Normal waste treatment with these restrictions requires a large capital investment. In addition, the company could not afford to send parts out for zinc phosphate processing because long turn-around times make it difficult to satisfy customer just-in-time delivery requirements.

To address these problems, Birchwood Technologies officials proposed a water treatment system that utilized a combination of ion exchange and the Near-Zero Water Recycler System. The design of this system is to keep rinse waters in good condition while reducing overall water consumption dramatically and enabling it to operate as a self-contained process line.

Zinc Phosphate finished parts using the MicroLok MZN Near-Zero process provides corrosion protection when in storage and break-in lubricity when put into operation.

The Near-Zero system collects the rinse water discharge from the rinse water in tank #2 following the cleaning station. The rinse water pumps through a series of filters to sequentially remove free oil, emulsified oil, and detergent residue, thereby partially purifying the water. The pH of the rinse water is also monitored and adjusted, as needed, maintaining a near neutral level. Besides oil and detergent residues, the water contains measurable quantities of sodium, which is not removed from the water, but allowed to build up. The chemical tanks in the process line can tolerate a moderate amount of sodium. As a result, a partial purification is all that is needed in order to successfully operate the process.

The ion exchange system purifies and recycles the rinse water in tank #5 following the MicroLok processing. Purifying the water is done through sequential filtration units that remove the organic compounds, then the positive dissolved ions, then the negative dissolved ions. The result is pure, de-ionized water that is fed back in to the rinse tank for re-use. The only maintenance needed is periodic regeneration of the resin tanks to remove the zinc content. This service is performed by an outside regeneration facility that assumes ownership of the chemicals collected in the resin tanks.

The rinse water continually circulates through the Near-Zero and ion exchange system, then back through the process line, thereby creating a constant 10-gallon per minute water flow in the rinse tank, and about once a month, the Near-Zero system needs purging. The rinse water, at this point, carries elevated sodium content that can be disposed of in one of two ways: It can be sent out for non-hazardous disposal with a waste hauling company; or, in areas where conditions allow, the water can be sent to the city drain as non-hazardous discharge.

The process rinse tank is then re-filled with fresh tap water, the filter elements are changed out, and the entire process begins anew. This monthly change-out schedule is usually all that is needed to keep the system operating efficiently. The Near-Zero Water Recycler, and ion-exchange system can be configured in a variety of sizes to match up with the capacity of the main process line.

The Near-Zero Water Recycler enables the process rinse tanks to operate as closed-loop rinses, using filtered water rather than fresh water, leading to a monthly consumption of less than 1,000 gallons versus the original 90,000 gallons – a 99% reduction from the normal levels. It also saves money since a discharge permit and sewer sampling are not necessary since water does not enter the drain.

Overall, the Oklahoma company achieved its goal of high quality in-house zinc phosphate finishing, with a 30-minute turnaround, while operating the system as a completely self-contained process line with no discharge to the drain.

The MicroLok MZN zinc phosphate process line was supplied by Birchwood Technologies, installed by the customer, and had factory tech support to train the operators on the proper operation and maintenance of the system as well as to provide follow-up support.

The MicroLok MZN zinc phosphate finish complies with MIL-DTL-162326, Type 2, Classes 1, 2, and 3.

Clean water is getting scarcer. Only a few states have enough water to comfortably supply demand, and even in those areas, there are water restrictions. In many states, a critical water shortage affects residential water consumption. Corporate water usage is increasingly more tightly controlled. In many areas, the cost of water is less important than the availability of water. With this in mind, the ability to operate with limited water consumption often means the difference between successful operation and not operating at all.

Modern industry benefits society by being green and conserving natural resources, but there are also benefits for industry itself. With the help of the Near-Zero Water Recycler and ion exchange, the challenge for conserving water becomes easier.